Tom's Guide Verdict

The XYZ Nobel 1.0 is a promising device that brings SLA printing to a new, low price point of $1,500. But there are too many quirks and problems to make it a winner.

Pros

- +

Produced attractive, clean prints

- +

Simple to set up

- +

Printing process is straightforward

Cons

- -

Prints showed some layering

- -

Some fine details were not well printed

- -

Much slower than other SLA printers

- -

No Mac software support

Why you can trust Tom's Guide

Who it's for: Designers and artists who want to produce fine prints of small models.

XYZprinting is breaking new ground with the Nobel 1.0, a stereolithography (SLA) resin printer that costs just $1,499 and can produce far more-detailed objects than mainstream FDM (plastic) printers can. With other SLA models costing a lot more — take, for example, the $3,299 price tag of the Form Labs 1+ — the Nobel 1.0 puts resin printing into the hands of home users. The Nobel 1.0 does a good job of producing intricately detailed 3D prints for objects like jewelry, engineering models or other models, although there are some compromises: It is much slower than other SLA printers, supports a limited range of materials and struggles with some fine details.

Design: Simple and plastic

The Nobel 1.0 has a fairly simple, straightforward design. A translucent-orange plastic hood covers the print area to block harmful UV light, while still allowing you to look inside and check a print's progress. Underneath the hood, you'll find a support holding the removable print bed. This bed moves up and down via a motor in the base; as the print bed is raised one layer at a time, the print is gradually formed. You remove the print bed by twisting the large knob and sliding the bed out.

The resin sits under the print head in a tray with a clear bottom that allows the UV laser to shine through, solidifying each layer of resin. The print bed rises for each layer of the print. Most SLA printers require you to manually fill the resin tray, but XYZprinting has come up with a neat mechanism that automatically pumps resin from the container into the tray, refilling the tray as required during printing.

The largest print that the Nobel 1.0 can create is a cube measuring 5 x 5 x 7.9 inches, for a total of 197.5 cubic inches. That's a decent size for an SLA printer, as these devices tend to be smaller than their filament-melting cousins. For example, the $1,299 Lulzbot Mini, which prints with filament, can manage 6.2 x 6 x 6 inches, a total of 223 cubic inches. The Form 1+ SLA printer can manage 4.9 x 4.9 x 6.5 inches, a total of 156 cubic inches. That said, SLA printers are usually used for smaller models, so print volume isn't a major criterion.

If you lift the hood in any direction other than straight up after the Nobel 1.0 finishes the print, you can knock into the print or the print bed, possibly damaging them. The Form One+ has a better solution: a hood on a hinge that tilts the cover back.

MORE: Top-Rated 3D Printers on the Market Now

Get instant access to breaking news, the hottest reviews, great deals and helpful tips.

It is not easy to switch resins with the Nobel 1.0, either, as this requires draining the auto-fill system and cleaning out the resin tray. XYZprinting also recommends doing this if you are not going to be using the printer for a few days, so the resin doesn't set. XYZ recommends disposing of this resin rather than using it later. The Form 1+, on the other hand, has resin trays that can be removed, covered and stored, so you don't lose any trays. If you often change resin colors, the Form 1+ approach will be easier. But the Nobel 1.0 auto-fill system makes it quicker and easier to produce multiple prints.

Print Quality: Excellent, with soft resin

The Nobel 1.0 delivered excellent quality for most of our tests, creating clean models with fine detail, though some layering was visible on close examination. We tested the printer using the clear Crystal resin that XYZ provided.

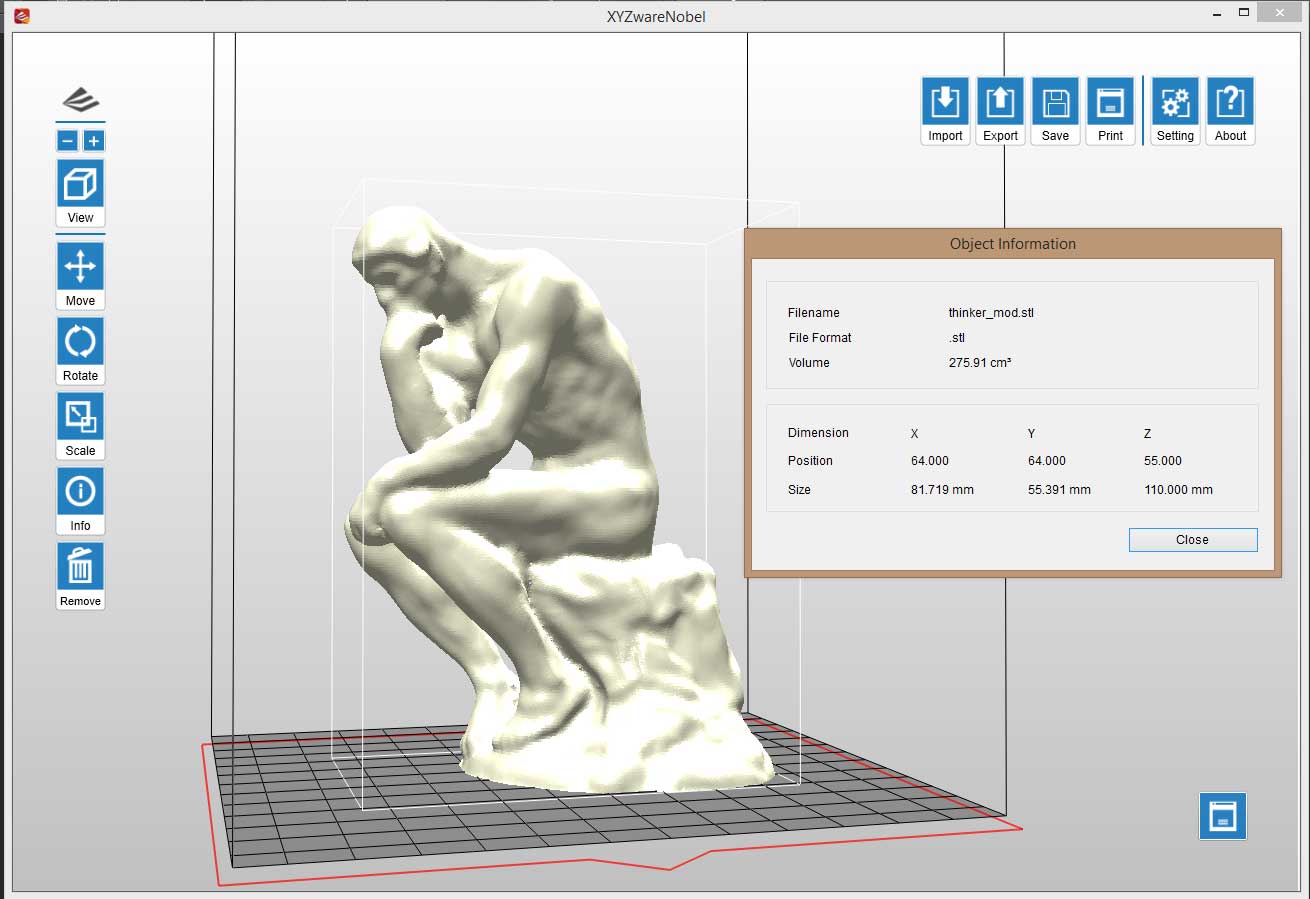

Prints of both our Thinker and geometric sculpture test models had good detail and smooth, natural curves. The Nobel 1.0 managed all of the complex geometry of the sculptures, producing overhanging surfaces and sharp, clean edges. The supports that the printer added to keep the print in place were easy to remove with a knife, leaving little or no trace.

I did notice some layering, with individual layers of both prints visible using all three of the quality settings that this printer offers. Layers were more visible than in the same prints from other, more expensive SLA printers, such as the Form 1+, and they detracted somewhat from the clear look of the Crystal resin.

The resin can be very soft straight out of the Nobel 1.0. On our test model of a set of gears, for instance, most printers produce rigid prints of the outer rings that hold the gears in place. With the Nobel 1.0, after printing and washing in alcohol, the rings were so soft that they could be easily squished.

The resin did get harder after curing the prints with UV light, by leaving them outside on a sunny day for a couple of hours. But I still could not build the set of gears because of another problem: The holes in some of the parts were inconsistent. The mechanism is built around three small cogwheels that have to fit onto pins on another part. But when I examined our printed gears closely, I found that some of the central holes were almost filled with resin, so they would not fit onto the pins.

I didn't receive any of the other color resins that XYZprinting offers, but I was able to successfully print these gears on the Form 1+ using a similar clear resin. It is possible that the other colors of resin may perform better, but it seems that XYZ still has some work to do.

Print Materials: Very limited

The Nobel 1.0 works only with resins from XYZprinting, sold in 500-ml bottles that cost $119 for two bottles. (You can't buy the bottles individually.) That's not cheap, though it's a little less expensive than the resin used in the Form1+, which costs $149 a liter, and the bottles last a fairly long time. For reference, our test model of the Thinker statue, which is about 4.5 inches high, used approximately 130 grams of resin, about $16 worth. I could produce three prints from each bottle, with some resin left over.

MORE: 8 Awesome 3D Printing Trends to Watch

XYZprinting sells five resin colors: Crystal (clear), Gray, White, Blue and Magenta. The bottles these materials come in have an NFC tag on the bottom, which the printer reads to verify them as genuine, and to track how much resin is left. This tagging prevents you from using resins from other manufacturers.

Setup: Simple and Straightforward

There are more steps involved in getting the Nobel 1.0 up and running than there would be for an FDM printer. After unpacking and turning the device on, you have to wait 10 minutes while the Nobel 1.0 runs a diagnostic test. Then you have to level the print bed, which involves waiting for it to lower before adjusting four screws that hold the print bed in place to get it flat against the base of the resin tray. After that, you put the resin bottle in place and connect it to the auto-fill mechanism with a couple of tubes. None of these steps are difficult, but they do involve a fair amount of waiting around: It took about an hour before I could set the first test print running. That's about twice as long as with an FDM printer, but roughly the same as on other SLA printers, which tend to be more complex than FDM versions. A model of a ring is built into the device, and this is a good first test.

Print Process: Straightforward

The Nobel 1.0 can print from a connected PC or from a file on a USB thumb drive. Frustratingly, there is no front USB port for the latter: I had to reach around the back of the Nobel 1.0 to plug the drive in. With an open tray of resin in this printer, you should avoid moving it, to keep from causing spills. As a result, it's easiest to print from a connected PC using the XYZWareNobel software, which is available for Windows only. Mac owners are left in the cold.

This program is quite straightforward, with all of the basic features easily available from the icons on the left. With XYZWareNobel, you can load models (in STL format only), move and scale them, and export the files for printing from a USB drive. The software also controls the printing process, but you don't get much feedback on this. Other software like MatterControl shows how the print is progressing in exquisite detail, showing you exactly which bit of the print is being created; XYZWareNobel gives you only basic information, like how much longer the print has to run and how much resin is left.

After you remove the completed print from the print bed, you wash it in alcohol to remove any unset resin. XYZ includes a scraper, plastic tub and gloves for this purpose, but no alcohol. That's easy to find, though: A standard bottle from the drug store with more than 75 percent alcohol content does the job. After you wash the print for 10 minutes and dry it, your print is ready. This process was very easy, if a little messy. I had no problems removing the prints from the print bed with the included scraper and washing them.

Print Speed: Slow

The Nobel 1.0 is not a fast printer, taking between 10 hours and 21 minutes on the 0.1mm preset and a lengthy 29 hours and 6 minutes on the highest-quality, 0.05mm preset to print out a 4.5-inch-high Thinker model. That makes this printer much slower than the Form Labs 1+, which took 6.5 and 12.5 hours on those two presets, respectively, with similar layer heights. FDM printers are generally much faster: The LulzBot Mini took a little more than 7 hours to produce a similarly sized print.

Bottom Line

The Nobel 1.0 brings resin SLA printing to a new price point that competes with FDM printers — offering the advantages of different materials and cleaner prints. The Nobel 1.0 does a decent job of printing in resin: Larger prints like our Thinker figure are undeniably attractive, but it is slow and struggles with the fine details that models like our gear set require. The printer is also considerably slower than more-expensive SLA models like the Formlabs Form 1+. So, the XYZprinting Nobel 1.0 is a significant step forward in making SLA printing cheaper, but there are compromises.

- 3D Printing Services Reviewed: Do They Really Work?

- How to Buy the Right 3D Printer

- Watch This 3D Printer Make Objects From Liquid

Follow Richard Baguley @rbaguley or on Google+. Follow us @TomsGuide, on Facebook and on Google+.

Richard Baguley has been working as a technology writer and journalist since 1993. As well as contributing to Tom's Guide, he writes for Cnet, T3, Wired and many other publications.