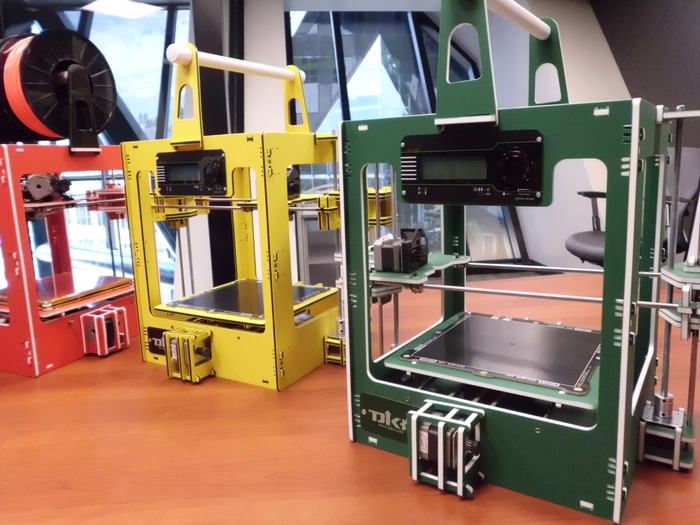

Build Your Own 3D Printer with Snap3D

With its simple and modifiable structure, the Snap3D printer — now on Kickstarter — has something for both beginners and advanced users.

Three-D printers can make just about anything. But can you make a 3D printer?

A new Kickstarter project, the Snap3D Printer by Tjiko Labs, was especially designed so that owners can assemble and reconfigure it themselves. No nails, soldering or wiring required — the pieces snap together like K'nex or Legos, with a few zip ties to keep some of the more delicate parts in place.

Luc Nikema, the founder of TJIKO Labs, said users should be able to assemble the Snap3D printer in less than two hours.

MORE: Best 3D Printers 2013

"Building a 3D printer is not easy … On the other hand, people can just go and buy a 'box' ready to print," Nikema told Tom's Guide. "[Snap3D] is between the two extremes … There's a huge satisfaction to be able to build your own product."

Snap3D is far from the first DIY 3D printer. It's part of the RepRap Project, an open-source effort to make a self-replicating 3D printer.

At $799, the Snap3D is almost twice as expensive as a typical RepRap kit, but is far easier to assemble and doesn't require any electrical knowledge.

Sign up to get the BEST of Tom's Guide direct to your inbox.

Get instant access to breaking news, the hottest reviews, great deals and helpful tips.

The Snap3D's simple structure was actually very hard to achieve. Nikema spent two years working on the design to make it both functional and intuitive.

The design is partially modular, meaning there are several different ways to assemble the pieces into different kinds of printers. People new to 3D printing can just follow the directions to get a functional 3D printer, but more advanced or enthusiastic users can experiment with the printer's design by reprinting its structural parts and replacing broken parts. Users can also tweak their designs to accommodate other pieces and create different printing experiences.

For example, the part of the Snap3D printer that holds the extruder — the nozzle that layers plastic in a specified design to create a 3D-printed object — is large enough to hold several different types of extruders, allowing owners to experiment with different extruder types and print styles. Many printers allow users to replace extruders, but the Snap3D's format is one of the more adaptable versions.

In terms of performance, Snap3D is in line with other 3D printers in its price range that are intended for home use. It can print in the three cheapest and most common 3D printing materials: ABS, PLA and Nylon, and the device is large enough to print objects up to 8 cubic inches (131 cubic centimeters) in dimension.

Nikema demonstrated an early prototype of the Snap3D printer at MakerFaire 2013 in New York City, where Tom's Guide got a hands-on experience with the device, and we got to try assembling part of it.

"We wanted to come up with a very inexpensive, cheap 3D printer that … even people who don't have any technical background would be able to use and assemble," Nikema said.

The Snap3D printer is currently on Kickstarter, where it needs a minimum of $25,000 to be funded. To date, the project has raised $3,961. As per Kickstarter's rules, if you "back" a project by pledging money to it, that money is only paid if the project is successfully funded. At that point, backers will also receive the items associated with their pledge. (Otherwise, you get a refund.) To get an unassembled Snap3D printer kit requires a pledge of at least $799. A pre-assembled Snap3D is $999.

In comparison, the Cubify Cube 3D Printer is $1,299, and the MakerBot Replicator 2 is $2,199. A Solidoodle 3D printer starts at $499, however, and comes pre-assembled, so if you aren't interested in the Snap3D's DIY features, then it might not be the printer for you.

Email jscharr@techmedianetwork.com or follow her @JillScharr and Google+. Follow us @TomsGuide, on Facebook and on Google+.

Jill Scharr is a creative writer and narrative designer in the videogame industry. She's currently Project Lead Writer at the games studio Harebrained Schemes, and has also worked at Bungie. Prior to that she worked as a Staff Writer for Tom's Guide, covering video games, online security, 3D printing and tech innovation among many subjects.