Scientists Build 3D Printer for Tiny Nano-Models

Researchers in Austria have developed a 3D printer that can create models on a nano-scale.

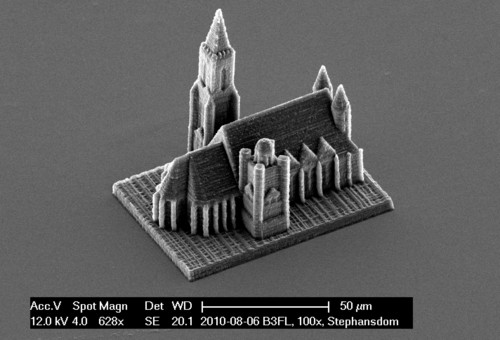

Using a method called two-photon lithography, the printer at the Vienna University of Technology was able to print a 285 µm race car as well as a 75 µm model of the St. Stephen's cathedral in Vienna.

In contrast to usual 3D printers, the device uses a liquid resin as well as a laser to harden the material when targeted by the laser light. The system supports up to 100 layers that consist of about addressable 200 lines each. “Until now, this technique used to be quite slow”, said Juergen Stampfl from the Institute of Materials Science and Technology at the university. “The printing speed used to be measured in millimeters per second – our device can do five meters in one second.”

100 layers of the material can be covered in about four minutes, the researcher said.

The increase in printing speed means that the technology can now be applied to larger and more complex objects. The scientists said they are now developing bio-compatible resins for medical applications, which can be used to "create scaffolds to which living cells can attach themselves" in a process that would result in a biological tissue. The 3D printer could also be used in nano-technology, the researchers said.

Sign up to get the BEST of Tom's Guide direct to your inbox.

Get instant access to breaking news, the hottest reviews, great deals and helpful tips.

Douglas Perry is an author and journalist from Portland, Oregon. His many articles have appeared in the likes of Tom's Guide, Tom's Hardware, The Oregonian, and several newspapers. He has covered topics including security, hardware, and cars, and has written five books. In his spare time, he enjoys watching The Sopranos.

-

dogman_1234 News like this gets me exited about the future for some reason. Maybe because it is cool?Reply

-

memadmax OOOH, this is good.Reply

Oh oh, wait a sec....

Que the Apple lawsuit in:

5.

4.

3.

2.

1....... -

outlw6669 Now this is quite an amazing tech!Reply

Just as a rough eyeball measurement, I estimate that each line on their print is 2µm wide (roughly 50µm width and looks like 25 lines in that space).

Just think about that for a second.

With just a little tweaking I would expect they could reduce each trace to 1.5µm, at which point they could essentially print a 386 Processor!

Really though, medical applications are the most promising for this.

Break a bone? Major laceration? Major surgery?

Just 'print' it back together for a cleaner and faster recovery! -

madooo12 can they used with silicon, phosphorus and boron, if yes it would be greatReply

think about printing your own chips at home -

freggo pabeaderAnybody else notice the date stamp on the picture? 2010?Reply

That's the date the printer started printing.... just finished :-)

-

thegreatms pabeaderAnybody else notice the date stamp on the picture? 2010?Reply

Research takes a long time.

Patents take a long time.

Getting Published takes a long time.

Especially when there is no immediate commercial application. -

dgingeri Replicators! This is a direct lead to Star Trek style replicators! I love it!Reply

When these become fast enough and cheap enough, they'll replace small circuits, leading to custom circuitry, leading to more sophisticated versions, leading to handling multiple materials, leading to more sophisticated versions, leading to producing full electronic devices, leading to more sophisticated versions, leading to producing other types of items, leading to producing food, leading to lower poverty rates, leading to a better world. I love it! We'll have warp drive and phasers in 5 generations with this technology! The future is back!