Apple Has a Major Quality Control Problem

The company’s quality assurance seems to be going down the drain while its products’ prices keep soaring.

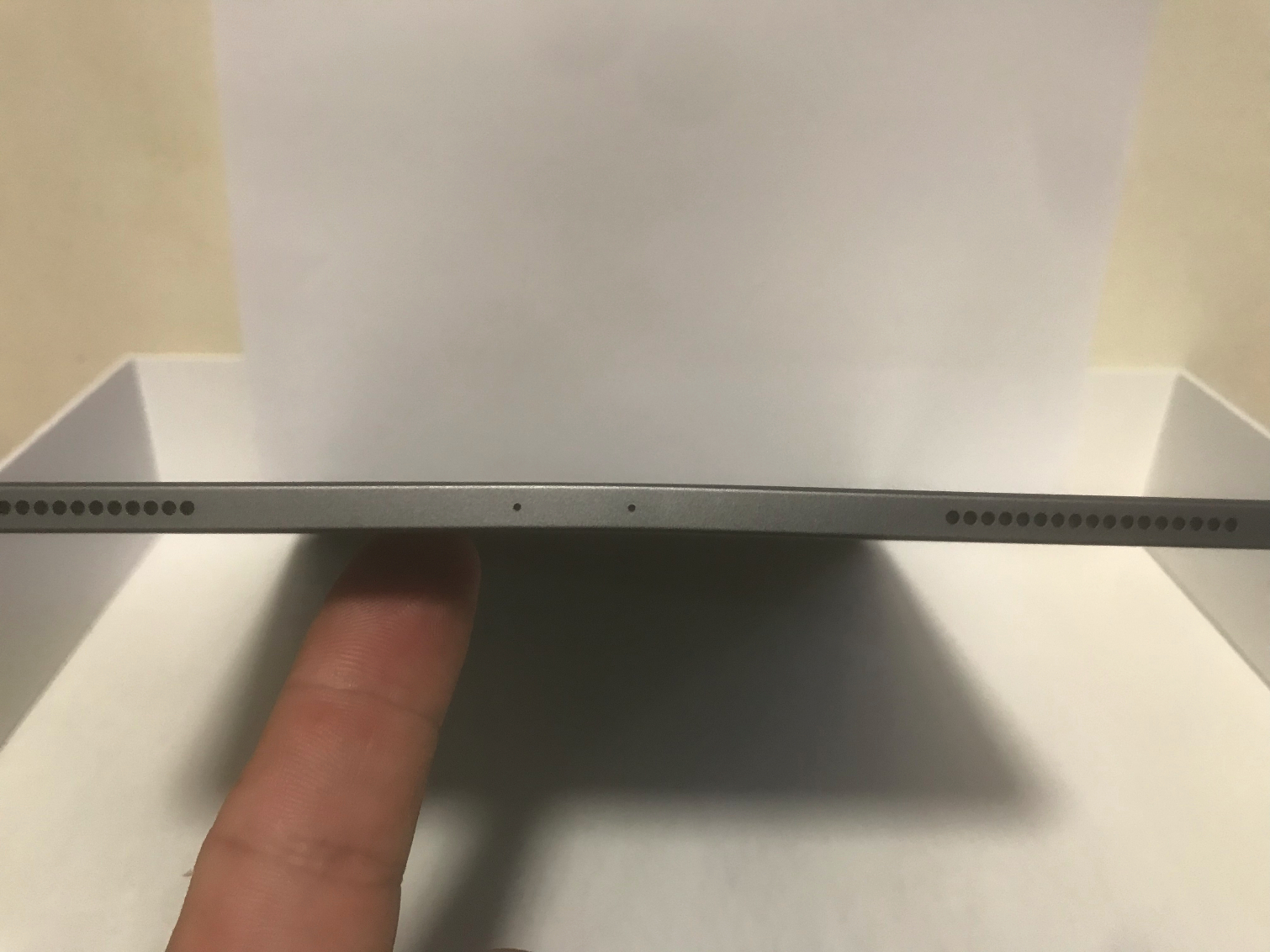

Apple has confirmed its latest hardware quality blunder: some units of the new iPad Pro are arriving to costumers with “a very slight bend in the aluminum chassis.”

Shockingly, Apple told The Verge that it doesn’t consider this to be a defect.

We knew that the new iPad Pro design could bend easily (as shown in the test video below), but there’s no excuse for some devices coming already bent from the factory. This is a device that can cost from $800 to $1900 depending on its configuration. Both iPad sizes can be affected by the problem.

The company says that this is a “side effect” of the cooling phase of the plastic and metal components during manufacturing process, which seems like bunk because it only affects some units and not others.

That’s not in line with all the publicity that Apple gives to its “ultra precise” quality manufacturing process every time it introduces a new product. Unfortunately, the factory-bent iPad Pro is not an exception but part of an increasingly problematic trend.

iPhone X

Apple recently announced that its iPhone X — sold all through 2018 — can exhibit a major factory defect on its screen that will make it unresponsive to touch, offering a “free” repair program for its $1,000 phone.

MORE: 9 Reasons the Pixel 3 Beats the iPhone XS

iPhone XS and XS Max

The iPhone XS came with three major complaints. Users or these devices — which starts at $1,000 and goes all the way up to $1350 for the 512GB version of the XS, and from $1,100 to $1,450 in the Max variant — reported batteries that don’t charge unless the displays are on, which Apple fixed in a iOS update. The same happened with the selfie beautifying effect, which came on by default and was later fixed in software.

A real hardware issue, however, is the iPhone XR's reportedly poor LTE and Wi-Fi reception, which echo the first iPhone antennagate. Like that infamous iPhone 4 “you are holding it wrong!” blunder, experts say that this new antennagate can’t be fixed with software.

Separately, PCMag found that the iPhone XR has considerably poorer reception than the iPhone XS, due to the quality of the former phone's antennas.

HomePod

Earlier this year HomePod buyers discovered that Apple's smart speaker left a nasty white ring on wood furniture. That's a slap in the face to people who spend $349 for the device. Apple updated its support page for the HomePod to address the issue. suggesting users place "your HomePod on a different surface." As it turns out, the Sonos One exhibited a similar issue, but that doesn't really help.

iPad Pro 2017

Not only the new iPad Pro has problems. Apple has acknowledged that the 2017 iPad — sold until November 2018 — is developing hardware quality problems: users are reporting a bright spot that appears about 1 to 2 inches above the home button

MacBook Pro

In addition to the iPhones and iPads hardware blunders, Apple annus horribilis has also affected its Macbook line in a big way. Last month Apple admitted a major problem in the solid-state drive inside the 13-inch MacBook Pro that affects a “limited number” of 128GB and 256GB drives, with users reporting actual data loss and failure.

MORE: My Month with the New MacBook Air: What I Love and Hate

Earlier in the year, Apple finally recognized that keyboards in various MacBook and MacBook Pro models from 2015 to 2017 were defective, offering a replacement program.

But if you think that Apple learned from this and fixed things with the 2018 MacBook Pros, you are sorely mistaken. Users of the new computers have reported severe throttling issues with the new Core i9 chips, thanks to the hardware chassis design, which the company kept from the previous generation. As a result, the CPUs can’t run at their full speed because the machine can’t dissipate heat. Reportedly, this makes the top-of-the-line and top-priced i9-equipped MacBook Pros slower than the cheaper Core i7 models under intensive work.

The new MacBooks also have sound distortion issues even at low volume.

Not even the Apple Watch gets saved from this QA cluster-you-know-way. A new lawsuit claims that Apple’s digital timepiece has a battery problem. Some watch batteries would swell until they cause the screen to crack or detach. Apple has acknowledged the problem and is repairing the watches.

What’s Going On?

Of course, many other companies have hardware design and manufacturing issues. But those companies don’t charge top dollar and boast about their extreme quality assurance process in keynotes and long ads narrated by Jony Ive.

Apple, which has had plenty of hardware problems through its history, can’t afford this onslaught of bad news in one year. Especially when they keep pushing prices up. There are no excuses for any of these blunders and certainly no space for ridiculous “bent iPad Pro chassis are not a defect” statements. Apple, you are handling it wrong.

Sign up to get the BEST of Tom's Guide direct to your inbox.

Get instant access to breaking news, the hottest reviews, great deals and helpful tips.

Jesus Diaz founded the new Sploid for Gawker Media after seven years working at Gizmodo, where he helmed the lost-in-a-bar iPhone 4 story and wrote old angry man rants, among other things. He's a creative director, screenwriter, and producer at The Magic Sauce, and currently writes for Fast Company and Tom's Guide.

-

COO2CTO "The price of excellence is very high".Reply

There are no shortcuts and "thermal cooling" causing a finished product to bend says a few things:

1. Product development and enough sample range to cover likely events for testing takes time and money. If your priorities shortcut these quality processes, you will see it in the finished products. It can't be hid.

2. There is a faulty decision making process somewhere in the Apple/Foxconn ethos. It isn't working. Reputation is everything and is being sold short while marketing is using algorithms to hike prices. This is a "right hand not knowing what the left hand is doing" and invalidates whatever marketing thinks the Apple reputation can carry to justify those price hikes.

It isn't justified with this well-researched list of what is known publicly.

3. I have noticed a trend coming from Silicon Valley and associated areas:

- They are sloppy.

Their own technologies have been beyond the development teams' ability of control, systems understanding and pro-activity with the quirks associated with these advanced technologies for at least several years now. We keep buying or subscribing to the products while they keep selling their own fans short in terms of faulty hardware and very faulty software. We buy "thermal cooling" bent screen frames and they say, "It's ok".

It isn't.

It IS showing a lack of care and lack of understanding of what it is they build and the associated thorough product development required to find these process weaknesses. IF they were employing solid thermal dynamics and associated materials science engineering to their designs and follow-throughs for technical trouble-shooting, consumers would not be seeing what we are seeing now anywhere near as frequently as we are.

Which is it, Apple? Faulty engineering , faulty engineering management or faulty accounting/cost control philosophy?

4. I am embarrassed for the conspicuous lack of concern for our private data as demonstrated by these breaches, deliberate development cycle data sharing and defensive verbage coming from silicon valley. I don't care what their policy is or what they deny. That does not, in any way, erase the facts of the events happening anyway. This is not adult communication, it is grade-school.

5. I'm not looking the other way at what Facebook's or Twitter's problems are. Rather, I am warning my employees to take care of their data and any data that they input to these systems. If the systems' owners cannot control their own technologies, then my employees are smart enough to know what to do. I do not tolerate co-dependence to sloppy considerations of any data handling, let alone private data handing.

In summary, Silicon Valley is in over their heads. Their own technologies are beyond their understanding, especially while considering the complexities of integrated systems these systems create and are a part of. The facts of events proves the endemic sloppiness "group think" usually falls into. Defensive explanations and those that say that obvious defects are "OK" reflect the same short-cut thinking which is, apparently, part of the ethos of product development and the unaddressed gaps in the relationships with marketing. -

Korey_4 I have an XR, my wife has an XS Max, and neither of us have antennae issues of any kind. My phone gets the same range/coverage as hers does. I actually have better reception than I did with the original Pixel (surprising to me given the "iPhones don't have the same quality of reception" all over the internet—though I wouldn't be surprised if Samsung has the best in the game).Reply -

ebinrock This is why Apple needs to let their iOS and Mac operating systems be installed on any hardware, not just their own. That way, if one particular manufacturer was constantly screwing up their quality control, you could always choose another to replace it with, provided they all met a particular universal standard (e.g., the ATX standard for desktop PC's, and variants thereof like Mini ATX, etc.). Personally, I'd like to see smartphones and tablets fully customizable and build-able from the ground up as well, using a similar universal standard (maybe with their own variants for different sizes, etc.).Reply

Finally, companies need to stop being so darned CHEAP to squeeze every last bit of profit out of buyers, and electronics manufacturing needs to come back to Japan and away from China, who's well-reputed for shoddy quality control. At least from what I've known from products in the 80's, and the one week I spent in Japan at an electronics factory in the late 90's, they've always been truly committed to quality control, through a meticulous and methodical mindset, a rarity these days. -

COO2CTO This is a good recommendation for some of the product issues discussed here. However, it does not eliminate the overarching philosophical drivers: I call it sloppiness - akin to what you are saying in your 2nd section. The Japanese are excellent systems integrators. They have gone way beyond where they started - copying parts is far simpler than making the parts operate with other parts into a reliable system. This is a cultural statement - they pay attention to details and what makes things work reliably. It isn't stated very much in the Apple system approaches, but what are they using at Foxconn? What is Apple pushing?Reply

Six Sigma/Lean etc. take a certain discipline that manufacturing on the cheap will not afford. It takes time and dedication - would we be seeing this much product defect on the consumer side if they were using it? Engineering has been reluctant to accept Six Sigma as part of their design processes since it is a creative effort, as is commonly used to push back against being measured. Manufacturing and production are not seen as being "creative", yet there is plenty of it to make the system produce reliably. You can have poorly designed products produced well.

I can see the problems with Apple's deployments - Jesus Diaz did a great job pulling that story together with these historical events. But, what are we really seeing the symptoms of?

21595061 said:This is why Apple needs to let their iOS and Mac operating systems be installed on any hardware, not just their own. That way, if one particular manufacturer was constantly screwing up their quality control, you could always choose another to replace it with, provided they all met a particular universal standard (e.g., the ATX standard for desktop PC's, and variants thereof like Mini ATX, etc.). Personally, I'd like to see smartphones and tablets fully customizable and build-able from the ground up as well, using a similar universal standard (maybe with their own variants for different sizes, etc.).

Finally, companies need to stop being so darned CHEAP to squeeze every last bit of profit out of buyers, and electronics manufacturing needs to come back to Japan and away from China, who's well-reputed for shoddy quality control. At least from what I've known from products in the 80's, and the one week I spent in Japan at an electronics factory in the late 90's, they've always been truly committed to quality control, through a meticulous and methodical mindset, a rarity these days.

-

john.valescu Another example of Chinese manufacturing prowess and quality control. Maybe customers can send them back for a new iWhistle or whatever is the next piece of Apple junk?Reply

-Helmut