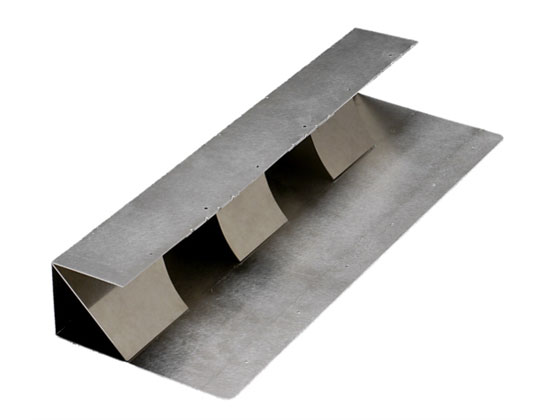

Making Metal Origami From Sheet Metal

New production process promises lower energy consumption, sturdy construction, and lower costs

A company called Industrial Origami has developed—what else?—a process that makes it easier to fold metal for production purposes. By perforating the metal at specific points, much like how craftsmen score paper to create neater folds, Industrial Origami claims that their procedure cuts down energy consumption. And, more importantly, on production costs.

According to the company, manipulating sheet metal to spec traditionally required expensive machinery and precise methods. Get something wrong on even a very tiny scale, and you basically waste the time and resources committed to the fabrication. The use of complicated automatons also means significant energy usage.

Industrial Origami's technology simplifies everything: it's just a matter of stamping the perforations on to define the folds, and using straightforward machinery to execute the folds. The side effects of this abridged procedure? Less energy is required to get the job done, and everything can be built from one piece of sheet metal.

Now for the real question: can Industrial Origami's folding metal process be applied to consumer electronics and all those other forms of tech we love? What if it was possible to create the shell of future smartphones, laptops, and the like on the cheap?

Industrial Origami

Sign up to get the BEST of Tom's Guide direct to your inbox.

Get instant access to breaking news, the hottest reviews, great deals and helpful tips.

Rico was a contributing writer at Tom's Guide. Based in the Philippines, Rico was plugged into the latest tech news to cover the latest future-gazing products and industry announcements. Rico no longer actively writes for Tom's Guide, and now works as a systems engineer. During his time at the site, he covered topics such as robotics, home office products and retro video games.

-

dxwarlock this isnt new...they have been doing perforation folding for 10 years.Reply

we used it a lot in the old machine shop with c&C mills to make the perforations.

my old VCR downstairs take the cover off its got that same thing on the folds. -

kalogagatya ClintonioWouldn't structural integrity be compromised quite severely?Reply

Yes it will. but it will depend on the geometry of the perforations. Some hole shapes will not concentrate stress enough to compromise its integrity that much:)

This is pretty usefull for a specific industry , where steel/aluminum bending is needed more (as an exclusive production process) than structural integrity. it will also allow a smaller machine a wider range of sheet thickness it can work with.

Probably the dificulties will lie on dimensional accuracy.. -

cadder You can buy parts for automotive modifications made using this process- things such as parts for offroad applications. In fact the parts come cut out but not bent, so they basically ship flat. You bend them and weld them together yourself. In this instance, after the parts are bent you weld up all of the seams so most of the strength is restored.Reply -

Glorian I've seen companies distribute car crossmembers/bumpers/suspension like this where the sheets come perforated and all you do is fold and weld. Makes it cheaper. Nice to see it going into other areas of construction.Reply -

p00dl3_h3r0 ClintonioWouldn't structural integrity be compromised quite severely?Reply

If more structural integrity is needed, one could always weld along the seems. However, the true strength I could see this kind of process have is in more accurate sheet metal prototypes, using smaller and cheaper bending machines.