How 3D Printing Will Save You Money

Printing household items can already save you money. As technology improves, 3D printing may offer more goods made locally or even at home.

Here's justification for splurging on a cool new 3D printer: It's actually a money saver.

Buying a 3D printer to make plastic iPhone cases and paper-towel holders at home can already save you money in the long run, according to a new study. That doesn't mean 3D printers will soon replace stores, let alone shut down factories in China or Vietnam. But it does suggest how the technology is creating a world where you could eventually make many products at home or at a local shop.

Printing money (savings)

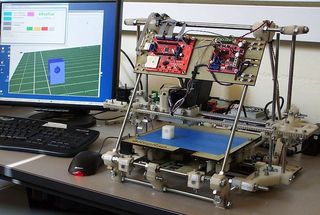

A 3D printer such as the open-source RepRap may not only pay for itself but actually save money by making just 20 household items — such as shower-curtain rings and safety razors — per year, said Joshua Pearce, a materials engineer at Michigan Technological University. His new study, wordily titled "Life-Cycle Economic Analysis of Distributed Manufacturing with Open-Source 3D Printers," challenges the skepticism of big manufacturers and the caution of 3D-printing experts who say the technology still has a long way to go.

"Today, we have the ability to print plastic, which actually opens up an enormous catalog containing thousands of products that we all have in our homes and use every day," Pearce said in an email. "The material selection is expanding quickly, and it seems likely that for many products, consumers will make their own rather than purchasing them."

MORE: How 3D Printing Is Changing Etsy

RepRap 3D-printer owners could save anywhere between $300 and $2,000 per year, depending on what 20 household items they make, Pearce found. RepRap owners can also continually upgrade their open-source 3D printer over time — even printing new components — as the technology improves, rather than having to buy a new 3D printer every few years.

Other costs of 3D printing

Despite these benefits, an open-source 3D printer is a big DIY project. A RepRap costs not only $575 for the parts but also about 24 hours of work to assemble them. And a beginner might need to first learn how to build it through workshops or online instructions. However, newbies can pay about double the price for an assembled RepRap. (That's still a bargain compared to highly polished models like the $2,199 MakerBot Replicator 2.)

Moreover, you shouldn't expect a 3D-printed plastic iPhone case, for example, to have the same quality or polish as a store-bought case. Today's 3D printers still create objects with very tiny steps or ridges on the sides rather than a smooth curve or finish. Pearce pointed out that you could smooth the object with nail-polish remover and paint it, but that's yet more work.

"Is the quality of the 3D-printed products on par with those that are manufactured conventionally and then purchased? No, not even close,” said Terry Wohlers, head of Wohlers Associates, a consulting firm focused on 3D printing.

Challenges for 3D printing

Today's 3D printers can make products tailored to unusual shapes and unique customer demands — they're good for making a limited run of expensive fighter-jet parts or a custom implant to repair a shattered skull (both have already happened). Yet the technology remains unable to produce objects made from multiple materials, and is too slow and too expensive for making many products, Wohlers said.

"Very inexpensive and relatively simple mass-produced products [such as plastic trash cans] will continue to be manufactured in big centers of manufacturing for a long time," Wohlers told Tom's Guide. "These types of parts, with production volumes of hundreds of thousands or millions, are not good candidates for 3D printing due to speed and cost."

MORE: What Doesn't Make Sense to 3D Print?

Nobody has done a conclusive study comparing the cost of 3D printing plastic parts locally to the cost of making plastic parts in a Chinese factory and shipping them around the world, Wohlers explained. But he and other experts believe that the factory model is still easily competitive with 3D printing. Part of the reason is that industrial-grade 3D printing requires more energy per item than traditional manufacturing does.

How 3D printing could go mainstream

But Richard D'Aveni, a professor of strategic management at Dartmouth University, says 3D-printing technology could improve rapidly over the next 10 to 15 years, to the point where it can compete with factory-made products. He compared the process to how PCs took over from mainframe computers in less than 10 years.

But D'Aveni, too, said that 3D printers have a way to go in order to become must-have household gadgets.

"You can make toys you expect to find in a McDonalds Happy Meal, but I think that it won't really appeal to people to buy a $300 or $400 machine [among the cheapest of today's 3D printers] to make Happy Meal toys," D'Aveni said. "The quality must go up, and the price of the machine must come down."

Yet 3D printing already offers other ways to compete with factory-made products, D'Aveni said. 3D printing allows you, the customer, to tweak the final design of a product and make it on the spot. D'Aveni gave the example of how toy stores might someday offer custom-made dolls with unique features — even based on a 3D scan of the customer's face or body. (One company, 3D Systems, already allows you to make customized 3D printed Star Trek action figures.)

A clever engineer might also design an array of simple 3D-printed parts that snap together as easily as Legos, to make bigger or more complex objects such as chairs and storage cabinets, D'Aveni said. It's a 3D-printing spin on the IKEA self-assembled-furniture process.

Order and print anywhere

The ability to print something almost anywhere also represents a huge advantage for 3D printing over factories — a benefit the U.S. military has recognized by putting 3D printers on ships and in distant battlefields to create prototype equipment and perhaps someday make replacement parts for vehicles.

Worldwide delivery company DHL is already thinking about how 3D printing might change where and how people buy products in the future. A 2012 report (pdf) by DHL considered the possibility of a "customized lifestyles" scenario for 2050 — a world where 3D printing in homes or local stores mostly replaces mass-production factories. In such a world, only raw materials and digital designs would cross national borders.

One small glimpse of that future is already possible through Kraftwurx, a Houston-based company that runs a digital marketplace for selling and ordering simple 3D-printed products, such as metal jewelry and plastic figurines, around the world. Kraftwurx's network of more than 100 3D-printing companies worldwide allows buyers and sellers to avoid international shipping costs and taxes on imported goods.

3D printing breakthroughs

That future could creep closer as 3D-printing technology begins to break through its current limits. 3D-printing companies continue to work on making cheaper, user-friendly 3D printers. Better software could allow more people to create and upload 3D-printer designs to share or sell online, or simply make it easier to print out items.

So what does this all mean for now? The 3D-printed watchband or showerhead you make at home today may not match the quality or aesthetic of a similar item bought on Amazon or at the local store. But if you have the time, money and patience to invest in a 3D printer, you can already begin saving money today, as long as the quality of 3D-printed items is good enough for you.

"Are consumers going to be willing to continue to pay $50 for an iPad stand if they can make one themselves for under a dollar or buy [a 3D-printed stand] on eBay for $2?” Pearce said.

Follow Jeremy Hsu @jeremyhsu. Follow us @tomsguide, on Facebook and on Google+.

Sign up to get the BEST of Tom's Guide direct to your inbox.

Get instant access to breaking news, the hottest reviews, great deals and helpful tips.

Tom's Guide upgrades your life by helping you decide what products to buy, finding the best deals and showing you how to get the most out of them and solving problems as they arise. Tom's Guide is here to help you accomplish your goals, find great products without the hassle, get the best deals, discover things others don’t want you to know and save time when problems arise. Visit the About Tom's Guide page for more information and to find out how we test products.

-

mi1ez You won't save any money unless you need exactly the right combination of things. It's a load of crap.Reply -

warezme I have a Makerbot Replicator 2 and while amazingly fast and accurate, it will take a very long time before it will save me money compared to what it cost me to purchase. However, there are instances when designing and printing your own solution can save you money in general. I have a nylon windshield wheel guide off a 1982 porsche 928s that broke. Cost to purchase tiny wheel $48, cost to print .35cents. I have a friends who is into cycling mainly high cost carbon fiber bikes. Some of the small parts are ridiculously high. Printing replacements to those would be simple and cheap.Reply -

yannigr Is it the same article with the list with all iPhone extra gadgets that no one wants to print? If yes it is a false article.Reply

BUT these machines ARE going to be an investment and not just an unnecessary expense like many stuff we are buying really often. I can't wait for 3D printers to start filling the shop shelves, to become REALLY mainstream devices like the 2D printers we are using today. -

ethanolson Holy cow, people. I worked in plastics for a while. Most plastics are not food grade, so you can't make cups and plates out of it and not increase your risk of numerous things, but mostly cancer.Reply

Also, these printers run on one kind of plastic (usually ABS... the stuff your monitor's frame is made out of) so you can't make things that require a different set of mechanical properties. The cellphone case is a poor example because the plastic isn't flexible enough to even get the phone in the case.

Stupid article from someone who thinks he's a thinker. Isn't it funny how "thinkers" get really excited about the stuff other "thinkers" say. We're doomed as a society. -

lamorpa You can make 'anything' as long as your 'anything' only includes things made out of (hard, brittle) ABS...Reply -

ethanolson Well... if we keep the discussion limited to the home-use 3d printers, then we're as limited as we've all described in our comments. Industrial printers have all sorts of different capabilities that aren't nearly as limited but the lay man doesn't have $180K to buy a printer... and there's no way they'll recoup that cost at home.Reply -

Grandmastersexsay 3D printers are 99% hype. Until they can do this with different alloys, this is just a magic bean.Reply

Of course there is a practical technology today that can accomplish what 3D printing might be capable of in the distant future. It is called a CNC router. They have been around for decades. -

back_by_demand Stick a shed load of eBay ads for abs components like cogs, frames, etc that usually sell for $5 or more, then sell them for $2 yourself, you will get thousands of orders and make back the cost of the printer and maybe even enough to give up work - for a couple of years - till world+dog owns a 3D printer and nobody buys abs parts online anymore or the cost is driven so low that it just isn't worth making them. Likely anything made from abs will have its design patented so a home user will print for personal use but if they try to sell it the original company will sue you into the ground.Reply