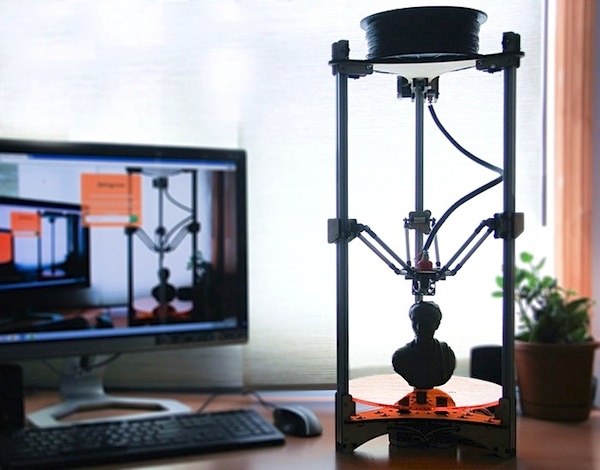

Deltaprintr Uses Six Arms for Quicker, Cheaper 3D Printing

Novel 3D printer designed by college students has reached more than half of its Kickstarter goal in first week.

A typical 3D printer has a printhead that moves back and forth, and up and down, spending a lot of time moving through empty space that will remain untouched.

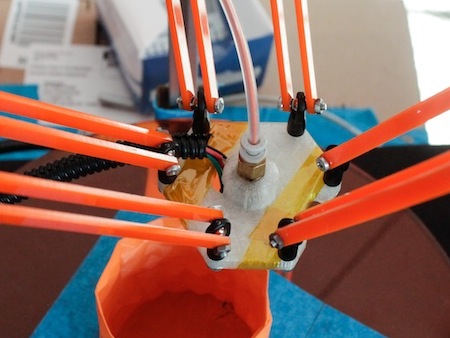

A new project on Kickstarter called Deltaprintr, launched by a group of college undergrads, takes a different approach. Most 3D printers have a printhead (which extrudes the hot plastic) mounted on a rod that it slides back and forth on. The Deltaprintr's single printhead, instead is held in place by six long mechanical arms that together direct the printhead precisely over the object it is printing. By moving the printhead only over territory where something will actually be printed, the process goes more quickly. The arms are mounted to, and move up and down on, aluminum posts to create 3D objects in an open space, rather than the usual enclosed box that most 3D printers use.

Shai Schechter, one of the creators of the Deltaprintr and a student at SUNY Purchase, said that the group can make the device for less than $500 by using cheaper materials, including a simpler printhead, fishing line to move the arms instead of the typical belts used in other 3D printers, and fewer total parts compared with those of other 3D printers. Schechter also claims that this simplified design should result in easier and quicker assembly for those who purchase the printer as a kit.

The early-bird special for the Deltaprintr kit had been $425 and rose in price as contributions came in and each reward tier sold out. Currently, you can get an early-bird special for an assembled Deltaprintr for $655. The creators say that because they are all undergrads, it was important to them to make a printer that was affordable for other students. While a handful of other printers, such as DeltaMaker, have used a similar configuration with six arms, few have been this inexpensive and simplified for easy assembly.

The Deltaprintr also comes with a calibration probe attached to the printhead that allows for automatic adjustments. The probe measures how level the printer is and then automatically adjusts the design of the object to make sure that it is printed correctly, without the user having to manually change the design or adjust the printer bed. Like many other consumer 3D printers, the Deltaprintr uses standard 1.75mm PLA (polylactic acid, and organic plastic) filament to print at a resolution of 100 microns.

The Deltaprintr's use of an open space defined only by tall aluminum posts, instead of an enclosed box, allows for larger objects than many other printers can manage. It currently supports cylinders up to 10 inches in diameter and 12 inches high, whereas other 3D printers often can't print objects that large because the print box that the printhead moves in is too small: MakerBot's Replicator 2 can print objects up to 6 inches by 6 inches by 11 inches, for instance, and the new Solidoodle 4 can print objects up to 8 inches by 8 inches by 8 inches.

But those limitations won't last forever: After the it Kickstarter campaign ends, Deltaprintr's creators promise to sell extensions to the aluminum beams, allowing you to build objects even taller than the original 12 inches. They will sell extensions of different heights, allowing users to get just as much build space as they want or need for a specific project.

Sign up to get the BEST of Tom's Guide direct to your inbox.

Get instant access to breaking news, the hottest reviews, great deals and helpful tips.

Deltaprintr's creators are seeking $195,000 for the project. They raised about $65,000 in the first 24 hours of the Kickstarter campaign and as of Dec. 12 have currently raised just over $100,000, with 23 days left to go. The actual 3D printers are expected to be delivered in July and August 2014, after production and testing.

Kelly Ohannessian is a freelance writer and editor. With more than 15 years of experience, she works with a focus on covering the creative aspects of the gaming industry. Her articles have appeared on Medium, Fast Company, Tom's Guide, Laptop Mag, Gamespot, and many more. Currently, she works as a manager at Brooklyn Game Lab.

-

Grandmastersexsay If this was a design that could make money, they wouldn't need to go the way of crowd funding.Reply

If you want to make stuff, and by stuff I mean something more substantial than plastic light switch covers, go take a machine shop class at your local high school or community college. Go buy a used mill for the same $500 they say they can sell this for, and see what you can do with it. Removing material is an infinitely more practical way to create 3D objects. 3D printing is 95% hype, 4% misunderstanding, and 1% potential. Don't let the pseudo techies tell you what the future is. -

WyomingKnott @grandmastersexsayReply

How many 3d printer articles are you going to respond to with that same comment about light switch covers? It's getting repetitive. -

Grandmastersexsay Every single one. I can't stand people selling false promises. How many dads are out there dreaming about making toys for their children, and invest their hard earned money in something that can't deliver? It's not right.Reply -

MiguelKendrick1 You know, it really takes time to search for the right filament supplier. The last time I bought PLA filament, it was terrible, it was too brittle when printing. Then I came across http://www.3d2print.net online filament shop couple of months ago. So far it's very flexible. Heat bed is 100°C depending on surface.Reply