3D-Printing Apps for Windows 8.1 Start to Arrive

3D-printer manufacturer MakerBot has released a driver for Windows 8.1, and other companies are soon to follow.

Microsoft's Windows 8.1 support for 3D printers is growing: MakerBot recently released the first Windows 8.1-compatible 3D-printing software driver — to be used with its Replicator 2 printer — and other manufacturers are working on drivers for their models.

The MakerBot driver, which is available now, works with Microsoft's latest operating system to control the printer without the source program having to know anything about the printer itself. For example, you could print from a 3D design program without having to worry about if the software supports the printer directly (just as you don't have to worry about compatibility issues with Microsoft Word and a regular printer, for example).

Instead, the driver and the OS handle the communications with the device, making it simpler to add support for new printers. MakerBot claims that its driver, which is based on its MakerWare software, makes 3D printing as easy as printing a document from Microsoft Word: You just hit Print, and the driver does the rest. This plug-and-play capability works only with the Replicator 2, not with MakerBot's older printers, such as the original Replicator, or 3D printers from other companies.

MORE : Best 3D Printers of 2013

Other manufacturers are also supporting the new Windows 8.1 driver system, with drivers coming soon for printers from 3D Systems' Cubify models and TierTime's UP Plus 2 printer. 3D Systems says drivers for its Cubify printers will be available in December, said Alyssa Reichental, a spokeswoman for the company. TierTime did not respond to messages from Tom's Guide, but a Microsoft spokeswoman told us that the drivers will be included in Windows Update "in time for the holidays."

Open-source printers, like the Prusa RepRap models, are also getting support. “[Microsoft] has one of my printers, and they used it for some development — so you can be sure RepRap printers are supported," Josef Průša, of the RepRap 3D-printer project, told Tom's Guide in an email.

"Microsoft offers a 3D-printing SDK [software development kit] to help hardware manufacturers develop 3D-printer drivers for Windows 8.1," Kris Iverson, principal software engineer at Microsoft who oversees the development, told us. Basic support for RepRap printers will be included in the SDK, he said, with improvements added in each SDK update.

Sign up to get the BEST of Tom's Guide direct to your inbox.

Get instant access to breaking news, the hottest reviews, great deals and helpful tips.

However, Průša doesn't think that the Microsoft initiative will have much impact. “To be honest, I'm not sure if it does anything innovative, and it is too generic," he said. "Manufacturers will still continue to supply their own control software, which will be better optimized and probably will push for it. But I can be dead wrong, and we might love it."

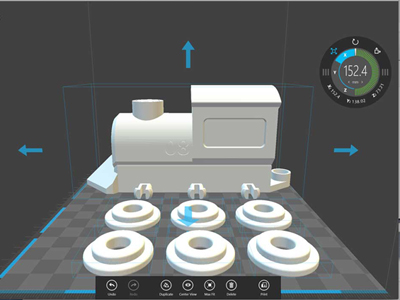

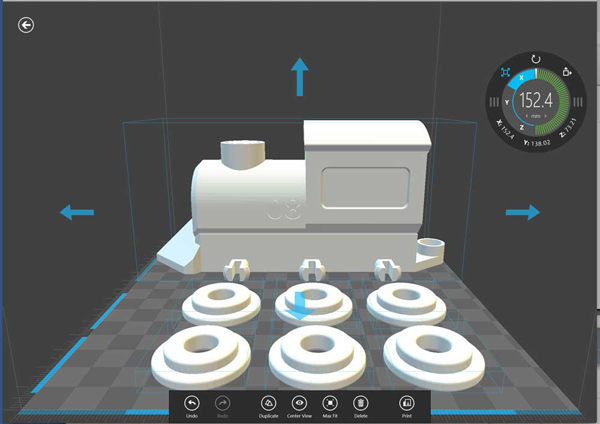

Microsoft has also released a simple 3D-printing app called 3D Builder. It is available from the Microsoft App store, runs on Windows 8.1 only and offers a selection of premade models that can be manipulated and printed. These prebuilt objects include a toy train set and track, as well as a number of household objects and miniatures. Some basic editing features are available, such as rotation and scaling, but objects can't be manipulated or built from scratch. Microsoft intends for this to be an intro to 3D modeling and printing rather than an alternative to advanced 3D modeling programs, such as Blender.

Follow Richard Baguley @rbaguley. Follow us @TomsGuide, on Facebook and on Google+.

NOTE: An earlier version of this story listed Josef Průša as the creator of the RepRap 3D-printer project. The RepRap project was created by Adrian Bowyer.

Richard Baguley has been working as a technology writer and journalist since 1993. As well as contributing to Tom's Guide, he writes for Cnet, T3, Wired and many other publications.

-

Grandmastersexsay The CNC milling machines that have been around for decades are vastly superior to 3D printers in every imaginable way except one: marketing.Reply

Seriously, what is with 3D printers being pushed so hard by the pseudo techies? The ones affordable to the general public are limited to weak plastic prototypes. For the same entry level investment, you could have a CNC mill that can work with aaluminum. If you look into the used market, a new world of possibility is open to you.

3D printing is a gimmick and will be so until they can work with metal and come in at under $1 million. -

warezme You overselling it dude. CNC milling is a subtractive technology and limited to mostly two dimensions. It needs drill heads, if metal, cooling systems, etc. Great for a big shop but not that great for your office. 3D printers are additive and can create full 3D objects with objects inside objects complete with detail overhangs. It's an apples and oranges comparison at best.Reply -

CaedenV @grandmasterReply

3D printers are more popular for several reasons. A milling machine is loud, cumbersome, requires at least some technical knowledge and assembly capability, and metal is relatively expensive. For your average do-it-yourself person who works a full time job, has kids, and a home enviornment where there are extremely limited hours (and space) for such equipment, this becomes an instant no-go.

Compare that to the promise (false as it may be) that you can go buy a 3D printer and some filament, download a blueprint, extrude a name or some simple design on it to make it your own, and press print, and have the printer quietly work on it overnight to have a product ready by morning. Obviously reality is never quite that simple, and things never quite work as advertized, but even with the hang-ups of 3D printing it is still going to typically be a simpler process with more flexibility than metal or wood-working equipment.

But the biggest thing that makes 3D printing more popular than CNC are the types of things being made. Custom light-switch plates for the kids. Cell phone cases, accessories, and other gadgets. Replacement gears and parts for small electronics which were plastic in the first place. Creative novelty and gag gifts for friends and family. RPG figurines for your nerd night out. Sure, metal would be more durable, but plastic (even cheap plastic) is going to be more than good enough for many of these applications, and in a lot of cases the preferred material.

Don't get me wrong, CNC is pretty cool stuff. If I ever have the spare time and money to burn later in life then it is something that I would personally love to at least play with. But for my life right now, as it is with most people, the 3D printer is a much easier point of entry, which will grow into a complete set of CNC and woodworking tools as time goes on. -

Grandmastersexsay You have no idea what you are talking about if you think milling machines are limited to two dimensions. In fact, I can't think of a CNC router that has less than 4 axes that isn't part of a specialized assembly process.Reply

As to your other point that milling machines can't produce 3 dimensional obects inside other 3 dimebsional objects, engineers have come up with a miraculous solution to that problem: use two pieces.

I think you are the one over selling working with plastic. -

Grandmastersexsay CaedenV, you nailed it as to why consumers are so excited about 3D printing: they are lazy idiots.Reply

If anyone is interested in making something more practical than custom light switch covers, 3D printing is not for you. Go take a machine shop class at your local community college. -

richardbaguley Grandmastersexsay, I understand what you say, but I would say that 3D printing is as revolutionary as CNC was when it first came out. The thing that makes it interesting is the ease; you don't need a workshop, dedicated space or other hardware. And that makes it easier to get into than CNC, especially for education; you could have a 3D printer in a schoolroom, but not a CNC.Reply

Of course, it has limitations, especially with the rather primitive state of the art at present. But I think that anything that gets more people into creating stuff themselves is a good thing.

Cheers,

Richard Baguley (author of this article)