Tom's Guide Verdict

The Form 3+ improves the ease and speed of printing over its predecessor, the Form 3, which was already our top choice for a resin-based 3D printer for professionals. There are cheaper options such as the Photon Mono X, but they require a lot more tweaking than the Form 3+.

Pros

- +

Fast printing

- +

High-quality results

- +

Lots of materials available, including flexible, dyeable and bio-safe

Cons

- -

Expensive, both for the printer and resin

- -

Can’t use third-party resins

Why you can trust Tom's Guide

Price: $3,499

Size: 20.9 x 15.9 x 14.8 inches

Print Size: 5.7 x 5.7 x 7.3 inches (237 cu. in.)

Type: LFS Resin (similar to SLA)

The Form 3+ from Formlabs replaces the Form 3, one of the best resin-based 3D printers we’ve tested. This is an area in 3D printing that’s seen a lot of competition in recent years, as a number of lower-cost models have sprung up, looking to challenge Formlabs’ pricier printers.

While devices like the Photon Mono X offer a lower-cost entry into SLA printing, the Form 3+ remains the 3D printer of choice for professionals who need dependable and high-quality 3D printing. Formlabs’ latest printer takes all the great features of the Form 3 and improves ease of use and print speeds to remain the ultimate 3D resin printer.

Formlabs Form 3+ review: Price and availability

The Form 3+ originally cost $3,499, but Formlabs subsequently announced that the printer's price was rising to $3,750, citing supply chain issues. The printer remains available directly from Formlabs. Even before the bump in cost, $3,500-plus is a lot to pay for a printer, especially compared to the Photon Mono X, which now costs around $500.

There are optional add-ons for the Form 3+. The Build Platform 2, which is designed to help you remove parts from the build platform, costs $229, while post-processing devices like the Form Wash and Form Cure cost $599 and $750, respectively. (That $750 reflects a $50 price hike on the Form Cure.)

Formlabs Form 3+ review: Design

Formlabs describes the Form 3+ as a LFS (Low Force Stereolithography) printer that uses a 250 mA UV laser to zap resin into a solid. The Form 3+ retains the same heavy, industrial-style design of previous Formlabs models, with an orange see-through plastic cover that folds up from the front to provide access to the build area.

The Form 3+ has a total build area of 5.7 x 5.7 x 7.3 inches, a total of 237 cubic inches, with a layer size of between 25 and 300 microns (0.001 to 0.012 inches) That’s much smaller than most FDM printers, and many SLA printers. If you need something bigger, Formlabs also offers the Form 3L, a step-up model that can print up to 13.2 by 7.9 by 11.8 inches: a total of 1,230 cubic inches.

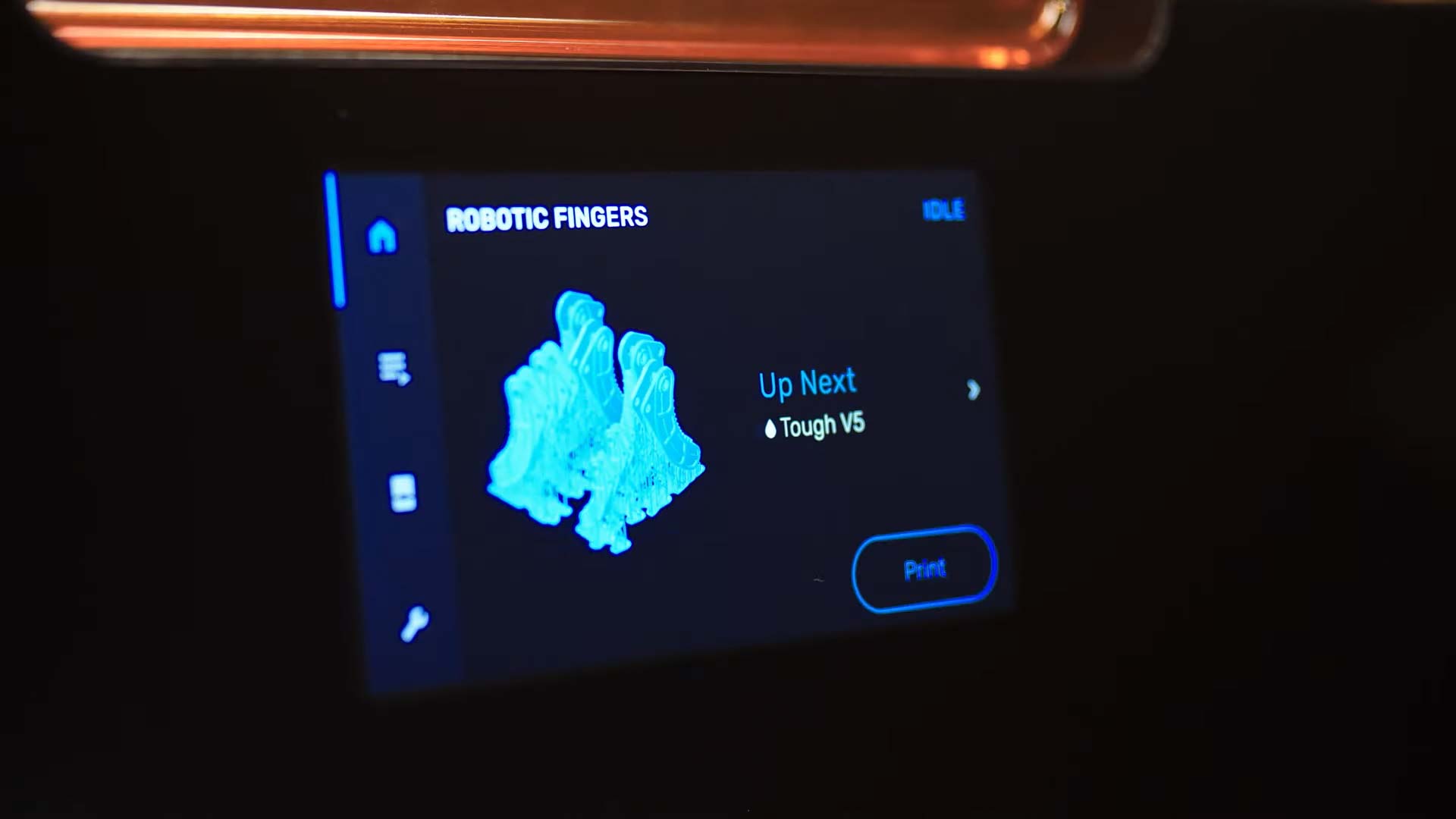

Below the lift-up cover of the Form 3+, you’ll find a large, clear touch screen that shows the status of the print and allows you to control prints in progress. Prints can be sent to the Form 3+ over Wi-Fi, ethernet, or USB connection to a computer running the PreForm software. There is also a USB port on the printer’s back for a USB drive.

The back of the Form 3+ is also where you’ll slide in the resin cartridge. This holds a liter of resin, and each cartridge is coded to tell the printer what type of resin is in it. The design means that you don’t have to touch the resin yourself — a small printer-controlled valve at the bottom releases the resin from the tank into the print tray. That’s a lot easier than filling the tray by hand, and means that the Form 3+ only dispenses as much resin as is needed for the print. That’s important, as resin left in the print tray can go bad over time.

The design of the print tray is also new for the Form 3+, with an improved mixer that moves the resin around before printing and a floating level sensor that measures how much resin is in the print tray. Much like the float in your toilet, this latter feature controls the flow of the resin so that there is enough to do the job, but no more.

The other new feature that we tested on the Form 3+ is the Build Platform 2, a revamped design for the platform that the print is built on. This is the part that is lowered into the reason that the print forms on, layer by layer.

Usually, this is a solid flat slab of metal, so when the print is finished, you then have to pry the print off with a scraper. The new Build Platform 2 design uses a flexible metal panel held in place by magnets. After printing, you use the handles on either side to release the panel from the magnets and bend it, which makes removing the print much easier: it usually just pops off without needing any prying or other persuasion. It’s an optional extra, but it is well worth the $229 if you are printing a lot.

Most of the other Form 3+ improvements are mostly to the user — these include an improved laser for faster printing and the addition of a heater.

Formlabs Form 3+ review: Accessories

In addition to testing the Form 3+, we also looked at the Form Wash and Form Cure. These two devices wash prints in alcohol to remove unfixed resin and cure the print with UV lights to finish it off.

Like the Build Platform 2, they’re optional additions to your Form 3+ setup: you can both wash and cure prints without them using a plastic container and a UV light. But adding them makes things easier and more effective: the Form Wash mixes the isopropyl alcohol to make sure that any nooks and crannies in the print are cleaned, and the Form Cure heats the print while it cures to make sure the resin is completely set. Together, they create an entire production line from loading the 3D model to the fixed print ready for use.

Formlabs Form 3+ review: Software and controls

You control the Form 3+ using one of three ways — from the touchscreen on the device itself, from the PreForm software, and through the Dashboard web interface. The Form 3+’s touchscreen is big, bright, and easy to see. From here you can start and stop prints, plus configure the printer and put it to sleep if you aren’t using it for a bit.

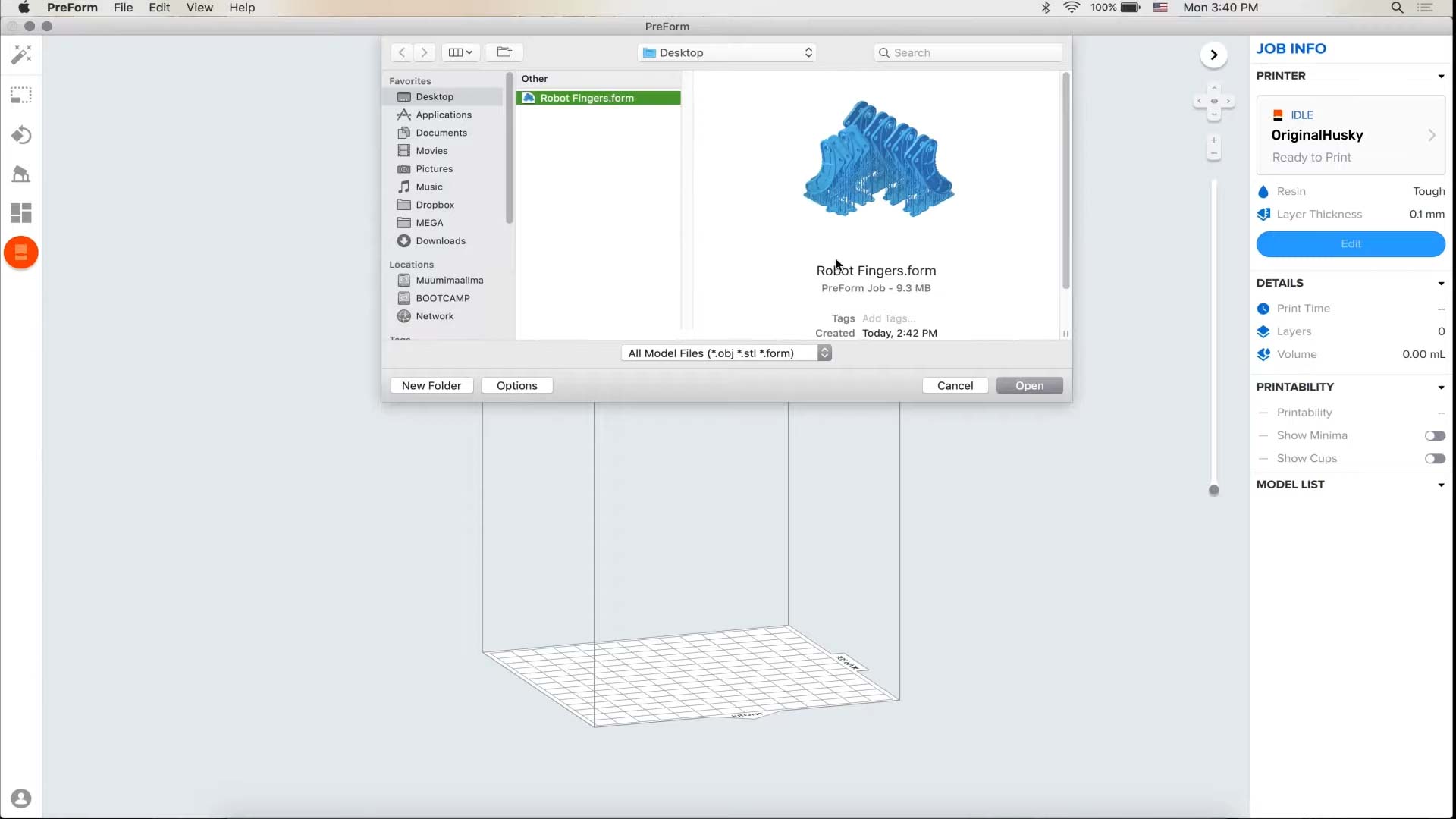

The PreForm software (available free for Windows and Mac) offers the main way of setting up prints and controlling the printer. This loads the 3D models, orients them for printing, and creates the print file to send to the Form 3+.

It’s an easy process, especially if you use the one-touch feature that handles most of the work for you. Because the Form 3+ communicates with the PreForm app, you don’t have to set up anything: it knows what type of resin is installed and how to configure the print for that. You do have to press a couple more buttons to send the file (and then go to the printer and start the print), so it isn’t quite one touch, but it is pretty close.

If you prefer to configure things yourself. PreForm allows you to load multiple models, shrink or enlarge them and move them about the build plate. Alternatively, you can load one model and clone it to print multiples in one print, a process called plating. You can also add print supports, or let the program add them automatically. Once your model is ready, you can send it directly to the Form 3+, save it or put it on a USB drive.

As for the dashboard, it’s a web-based service that allows you to monitor and control multiple printers, stop or start prints, monitor materials and check the print statistics. The Dashboard can have multiple users, so more than one person can use a single printer, or queue prints up on multiple devices.

Formlabs Form 3+ review: Print process

Once the print file has been sent to the Form 3+, it is time to get printing. Again, this process is pretty hassle-free: you select print and run through a couple of preparation steps (such as opening a valve on the resin tank and confirming that the print plate is in place); then, the printer gets on with it. The preparation process can also be done in advance: if you know you are going to be starting a print in a few minutes, you can prime the printer in advance, then start the print from the PreForm software.

The printing process itself is automated: you don’t have to watch it. The Form 3+ also includes a heater that warms the inside of the printer, a definite plus for the chilly basement I use for testing printers, as the resin doesn’t flow as well when it is cold.

This heater doesn’t extend to the resin tank, though, so filling the print tray from the tank sometimes took a long time, especially when switching materials. Formlabs told me that they recommend users put the Form 3+ into an air-conditioned or otherwise heated room, and that users should occasionally take the resin tank out, check the valve that the resin is dispensed from and shake the tank to make sure that the valve is not blocked.

After several prints timed out while waiting for the cold resin to drip out of the resin tank, I took to manually filling the tray before the first print, another process that Formlabs recommended. That’s more of an annoyance than a widespread problem with the Form 3+, though, especially for those who live in more civilized climates than New England in late winter.

Once the print is done, you can remove the print bed and finish the print. With the Form Wash and Form Cure devices, this involved putting the entire print bed into the Wash and setting it to run, which immerses and rinses the print in IPA (Isopropyl Alcohol) to remove any liquid resin clinging to the service. That process that takes about 20 minutes.

The Form Was automatically circulates the IPA to get into the print, then lifts the print out of the liquid to let it dry. Next, you remove your print from the print bed, then trim off the supports (a number of clippers and other tools are included with the Form Wash for this purpose). Finally, you put it in the Form Cure, which heats the print and bathes it in UV light to harden the resin. After that, the print is complete.

Formlabs Form 3+ review: Print speed

The Form 3+ is a pretty speedy printer when it wants to be. Using the Draft resin, a print of our 4-inch high Thinker test model took a little more than 2.5 hours. That’s fast because the Draft resin is designed for quick printing on prototypes. The Flexible resin took somewhat longer — 8 hours and 52 minutes for that same model because the Elastic resin uses thinner layers that take a little longer to fix.

That time is a bit quicker than the Form 3, which took between 10 and 17 hours to print. We can’t make a direct comparison, however, as the different printers use different resins. Still, it’s safe to say that the Form 3+ is a little faster than the Form 3.

Print speeds for the Form 3+ also compare well with other resin printers. The Photon Mono X, for instance, took more than 7 hours to produce the same size of print. Much of the speed of the Form 3+ is down to the draft resin we tested it with, but it is obviously a speedy printer that can crank out prints when needed.

Formlabs Form 3+ review: Print quality

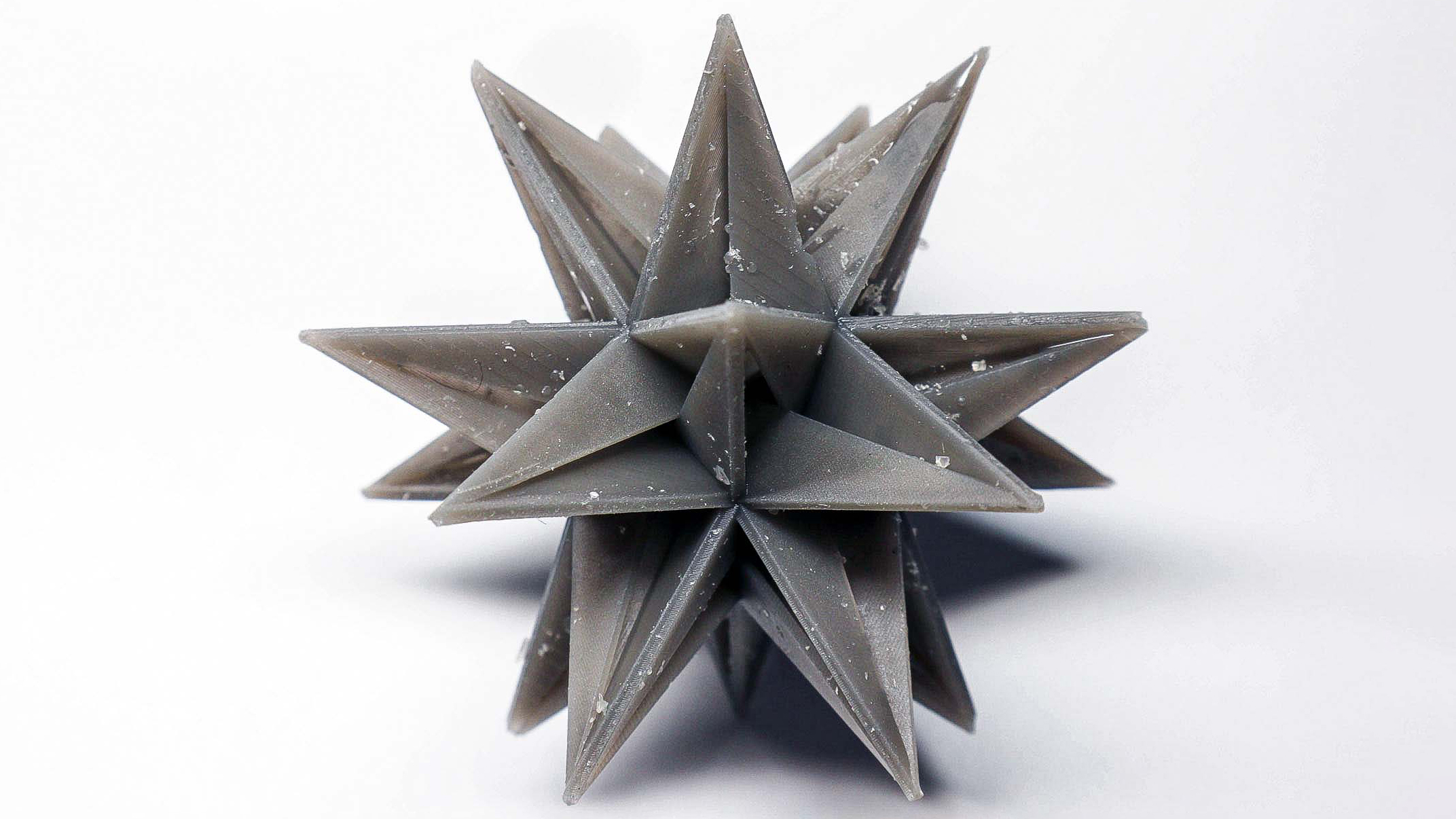

I was impressed with the print quality from the Form 3+, which consistently produced clean smooth prints with excellent detail and finish. The print quality depends a lot on the resin that you use, and we tried two in our testing — the Draft resin and the Elastic 50A.

Formlabs’ Draft resin produced very clean, smooth prints, but each layer of the print is 0.3mm thick, which in 3D printing terms, is a lot.

This does mean that the layers on prints are sometimes rather visible on flat edges and surfaces that are parallel to the print bed. In other areas, our test prints were very smooth, with well-reproduced details and smooth, organic curves.

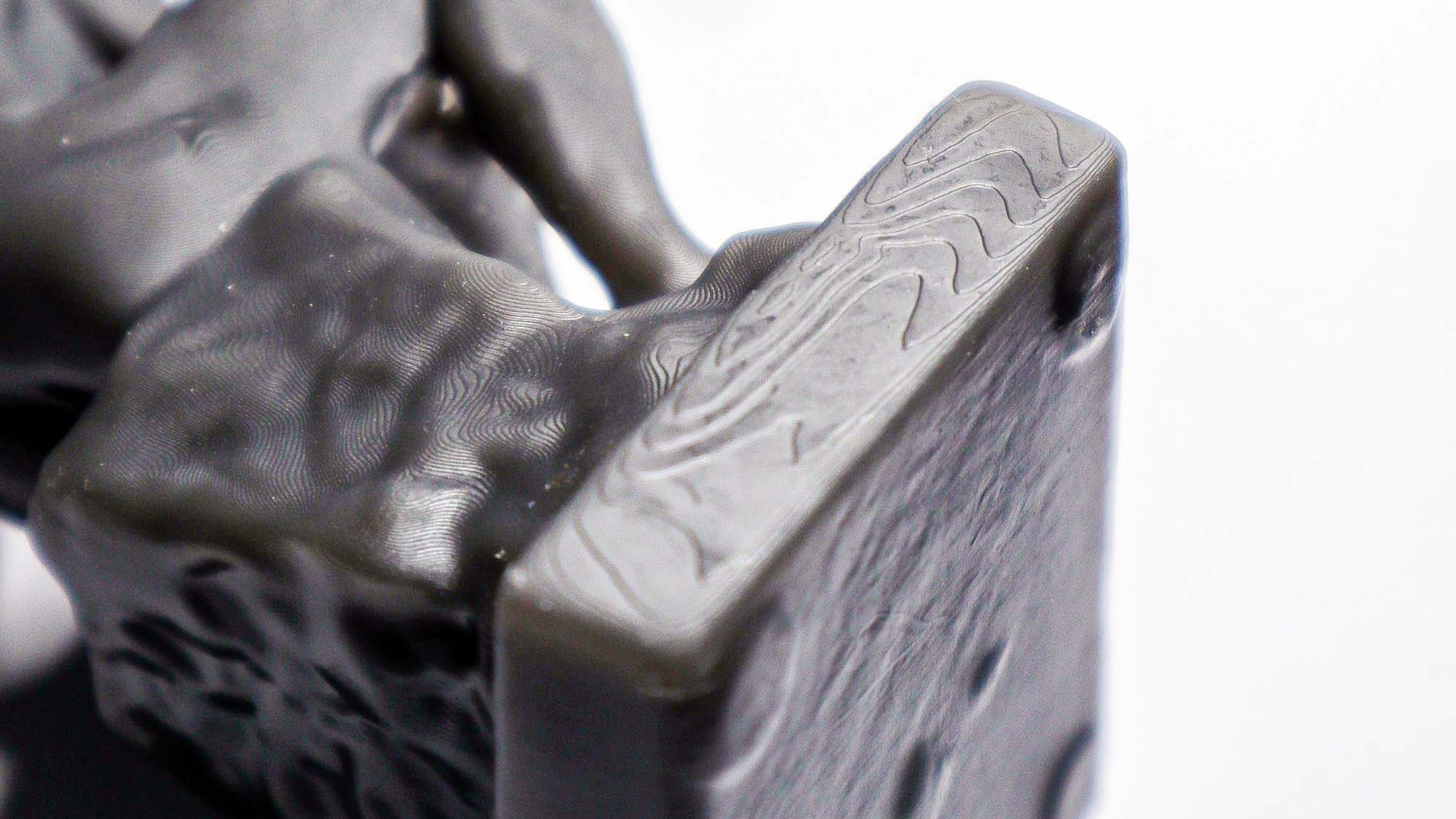

The print quality of the Elastic 50A resin was also excellent, with fine detail on our test prints. The prints in this material lived up to the elastic name: the clear resin is pliable and stretchable when cured, but is not rubbery: it holds its shape in fine details.

The elastic nature of this resin does mean that it is a bit of a pain to work with, and we did find that the supports for the prints left traces on the final print that were difficult to remove: little pock marks in the otherwise smooth surface of the print. These aren’t a big problem on the draft resin, as the brittle nature of the cured resin means that the supports come off cleanly.

But the elastic resin doesn’t snap off cleanly, and I had to trim off the surface marks with a sharp knife.This could probably be minimized by using less support material to minimize the parts that need to be removed, though.

Formlabs Form 3+ review: Materials

The Form 3+ is designed to use resins from Formlabs, which offer a very wide selection of resins for special purposes, including high-strength engineering, dental, jewelry, and medical use. The cost of these varies from $149 for the draft resin to $299 for the extra rigid engineering resin or the castable Jewelers resin. Medical-grade resins can cost up to $349. That’s expensive, but given that the more specialist resins have been through things like FDA testing so they can be implanted into your body, that’s not unreasonable.

Formlabs doesn’t offer different color resins: instead, they offer a color kit that includes clear resin and five dyes (Cyan, Magenta, Yellow, Black, and White), allowing you to make your own colors. They include 16 recipes as a starting point, but you will need to mix a full liter of resin to get the result: you can’t mix smaller amounts.

Older Form printers used to offer a feature called Open Mode that allowed you to use other resins, but this is not available on the Form 3+.

Formlabs Form 3+ review: Verdict

If 3D printing is a part of your daily work, the Form 3+ remains the printer to beat. It works quickly, is easy to set up and use, and prints with great quality. It’s not cheap, though: the package that we tested costs just under $5k. That could buy you two or three other cheaper printers, like the Photon Mono X, and a print finishing system.

But a printer like the Photon Mono X lacks the finish of the Form 3+, and prints from the former machine will require more handling and tweaking to get the best quality. You also don’t get the ability for multiple users to queue and manage prints.

Whether to pay up for the Form 3+ comes down to time and resources. If you don’t mind taking the time to tweak the printer, finish the prints then reprint them to get the results you want, a cheaper SLA printer will do just fine. But if you want to print and move on to the next task, the Form 3+ is the 3D printer to get.

Richard Baguley has been working as a technology writer and journalist since 1993. As well as contributing to Tom's Guide, he writes for Cnet, T3, Wired and many other publications.